Gear oil pump series

High viscosity pump series

Centrifugal pump series

Pump series for other purposes

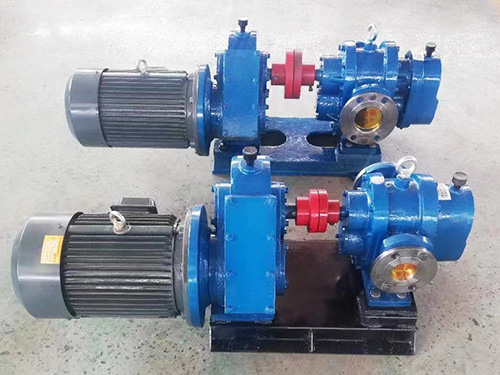

LC Roots pump

LC Roots pump is divided into two forms: belt drive and gear reducer drive. This pump has the characteristics of low speed, small volume, large flow rate, low power consumption, self suction, no need for oil introduction, and convenient use. It can be widely used for transporting petroleum and petroleum products (gasoline replaceable copper pump blades) and for transporting various oils and liquids in factories. Such as crude oil, paint, lubricating oil, glass glue, oleic acid, toothpaste, and light alkaline (soap processing) liquids; Food processing can transport various liquids, such as soybean milk, yeast, syrup, etc. Loading and unloading various oil tankers and tankers, convenient to use, and capable of working in both forward and reverse directions.

The LCW Roots pump is a modified solution for transporting asphalt and condensate oil. An insulation layer is added to the outer surface or end cover of the pump casing, and steam or thermal oil circulation is used to insulate the pump chamber, thereby ensuring continuous and intermittent operation of the pump.

Structural features:

This series of pumps consists of pump body, pump cover, shaft, gear, rotor, packing, pressure cover and other components. The pump comes in two forms: belt drive and gear reducer drive, which can reverse action. The two ends of the shaft are equipped with skeleton oil resistant seals, and a return oil device is installed in the middle to prevent air intake or oil leakage.

LC Roots pumps are used for the transfer, pressurization, fuel injection, and thin oil circulation of occupational oil media such as petroleum, chemical, metallurgical, mining, and power plants. They can also be used as smooth pumps in various types of mechanical equipment

The key component of LC Roots pump is the rotor, and the key to the rotor is its profile. The commonly used rotor profiles include arc tooth profiles, involute tooth profiles, and cycloidal tooth profiles. In recent years, the "arc → involute → cycloid" rotor profile proposed by Northeastern University has high air resistance, improved the performance of pumps under low pressure, and improved the pumping efficiency of pumps, making it widely used. I believe that there will be new and good rotor profiles for Roots pumps in the future, which will further improve the working performance of Roots pumps. The outer profile of the rotor cross-section is the profile of the rotor.

Overheating of the motor is a common problem in the operation process of Roots pumps. A detailed analysis and detection are as follows:

1. Scope of application (flow rate, head) Gear oil pump describes the requirements and selects the appropriate motor according to the series type spectrum;

2. The specific gravity of the medium is suitable for the motor equipment of the gear oil pump in Dajiang;

3. If the packing gland is pressed too tightly or the mechanical seal tension spring is adjusted too tightly, adjust the compression amount of the gland or mechanical seal tension spring from scratch;

4. The installation quality of Roots pump is poor, and there are conflicts or discrepancies between the motor and pump shaft. Check the installation quality and eliminate installation defects. Analyze each of the above conditions one by one, identify the true cause of motor overheating, and then repair and dispose of it according to the corresponding problems.

Technical parameters of LC Roots pump:

| Pump model | flow m3/h | working pressure mpa | Entrance and exit caliber mm | Allow suction heightm | Transmission form | power | power KW | efficiency % | Select number r/min | working temperature ≤°C | weight kg | Application scope | |||||

| Reducer model | Triangle code | Motor model | |||||||||||||||

| LCX-10/0.6 | 10 | 0.6 | 40 | 6 | ZD14 | A1778 |

| 3.0 | 62 | 400 | 140 | 167 | Diesel, engine oil, glycerin, petroleum, toothpaste, edible oil, heavy oil, etc | ||||

| LC-18/0.6 | 18 | 0.6 | 50 | 6 | ZD14 | A1778 |

| 5.5 | 62 | 400 | 140 | ||||||

| 4.0 | 62 | 140 | 219 | |||||||||||||

| LC-38/0.6 | 38 | 0.6 | 65 | 6 | ZD14 | B2350 |

| 7.5 | 65 | 400 | 140 | 269 | |||||

| LC-50/0.6 | 50 | 0.6 | 100 | 6 | ZL200 |

| 15 | 70 | 445 | 140 | 1160 | ||||||

| LC-80/0.6 | 80 | 0.6 | 200 | 6 | ZL200 |

| 30 | 70 | 209 | 140140 | |||||||

| LCQT-100/0.6 | 100 | 0.6 | 200 | 6 | ZL23.1 |

| 37 | 73 | 254 | 140 | |||||||

| LCQT-10/0.6 | 10 | 0.6 | 40 | 6 | ZD14 | B2350 |

| 3.0 | 62 | 400 | 140 | 167 | Gas oil, solvent oil, kerosene, etc | ||||

| LCQT-18/0.6 | 18 | 0.6 | 50 | 6 | ZD14 | A1778 |

| 5.5 | 60 | 400 | 140 | 219 | |||||

| 4.0 | 62 | 140 | ||||||||||||||

| LCQT-38/0.6 | 38 | 0.6 | 65 | 6 | ZD14 | A1778 |

| 7.5 | 65 | 400 | 140 | 269 | |||||

| LCQT-50/0.6 | 50 | 0.6 | 100 | 6 | ZL200 |

| 18.5 | 70 | 445 | 140 | 1160 | ||||||

| LCQT-80/0.6 | 80 | 0.6 | 200 | 6 | ZL23.1 |

| 30 | 70 | 209 | 140 | ? | ||||||

| LCQT-100/0.6 | 100 | 0.6 | 200 | 6 | ZL23.1 |

| 37 | 73 | 254 | 140 | |||||||

| LCXW-10/0.6 | 10 | 0.6 | 40 | 6 | ZD14 | A1778 |

| 3.0 | 62 | 400 | 140 | 167 | Asphalt, condensate oil, heavy oil, etc | ||||

| LCXW-18/0.6 | 18 | 0.6 | 50 | 6 | ZD14 | A1778 |

| 5.5 | 62 | 400 | 140 | 219 | |||||

| 4.0 | 62 | 140 | ||||||||||||||

| LCXW-38/0.6 | 38 | 0.6 | 65 | 6 | ZD14 | B2350 |

| 7.5 | 65 | 400 | 169 | ||||||

| LCXW-50/0.6 | 50 | 0.6 | 100 | 6 | ZL200 |

| 18.5 | 70 | 445 | 140 | 1160 | ||||||

| LCXW-80/0.60 | 80 | 0.6 | 200 | 6 | ZL23.1 |

| 30 | 70 | 209 | 140 | |||||||

| LCXW-100/0.6 | 100 | 0.6 | 200 | 6 | ZL23.1 |

| 37 | 73 | 254 | 140 | |||||||

Reasons and Solutions for Gear Pump Not Feeding

The reasons for gear pumps failing to draw material (also known as suction failure or cavit ...

2026-02-09

Why Gear Oil Pumps Cannot Be Used for Water Pumping

Why can gear oil pumps not be used for pumping water? This question touches on the fundamen ...

2026-02-02

How to choose a gear pump when transporting media that solidifies at room temperature

When transporting media that solidifies at room temperature, specialized insulated gear pum ...

2026-01-28

How to prevent gear pumps from clogging when pumping adhesive

The core to prevent clogging when using a gear pump to draw glue lies in strict operating p ...

2026-01-19